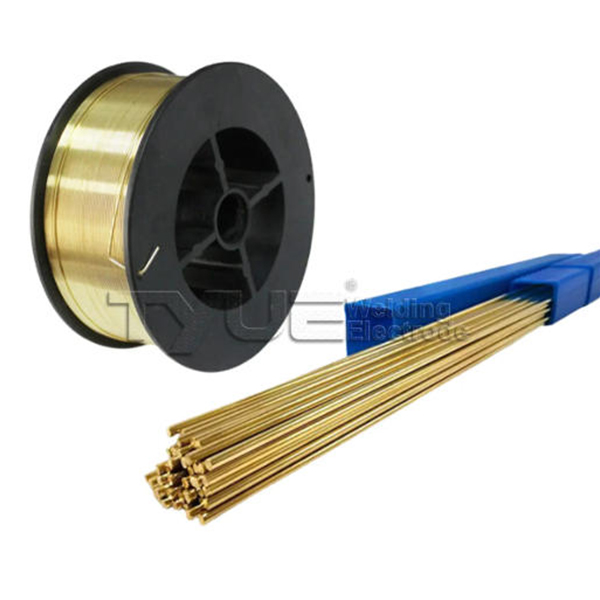

LubTooj Liab Alloy Vuam Hlaucais raws li AWS ERCu specification sawv cev rau cov hlau tshwj xeeb tsim rau cov txheej txheem sib koom ua ke zoo. Cov hlau tooj liab deoxidized no yog tsim los tsim cov khoom sib txuas ntom ntom, suab nrov nrog kev ua hluav taws xob siab. Raws li ib hom tshwj xeeb ntawm Cov Hlau Tooj Liab Welding Wire, nws yog qhov tsim nyog rau kev siv hauv cov txheej txheem vuam inert roj shielded, TIG thiab MIG vuam, ua rau nws tseem ceeb koom ua ke thiab surfacing daim ntawv thov qhov twg tooj liab cov yam ntxwv yam ntxwv xav tau.

Cov tshuaj lom neeg ntawm Cov Hlau Sib Xyaws Tooj Liab no yog tsim los muab kev ua haujlwm zoo tshaj plaws thaum lub sijhawm vuam. Cov khoom deoxidizing hauv cov hlau sib xyaw ua ke tiv thaiv kev tsim cov porosity hauv cov hlau vuam, ua kom ntseeg tau tias cov deposits tshwm sim yog khov kho thiab txhim khu kev qha. Cov qauv tshwj xeeb ntawm Cov Hlau Sib Xyaws Tooj Liab no feem ntau poob rau hauv qeb ntawm cov hlau sib xyaw ua ke tooj liab, muab cov yam ntxwv zoo heev thaum koom nrog cov hlau sib xyaw ua ke thiab pab kho ntau yam khoom siv tooj liab.

Qhov kev faib tawm ntawm noTooj Liab Alloy Vuam Hlauqhia txog cov khoom siv lub cev tshwj xeeb uas txhais nws cov kev ua haujlwm. Nws muaj qhov kub ntawm solidus kwv yees li 1020°C thiab dej kub ntawm 1050°C, tsim nws qhov ntau thiab tsawg melting rau kev txhim kho cov txheej txheem vuam kom zoo. Nrog rau qhov ceev ntawm 8.9 kg / dm³, Cov Hlau Tooj Liab no ua haujlwm tau zoo thaum lub sijhawm vuam tsis siv neeg thiab phau ntawv, muab kev pub mov thiab cov yam ntxwv arc sib xws.

Cov hlau vuam uas tsim los ntawm kev siv cov hlau tooj liab no muaj cov khoom siv kho tshuab zoo heev, ua tau raws li cov kev cai siv nruj. Lub zog tensile ntawm cov hlau vuam feem ntau yog ntawm 210-220 N / mm², nrog rau kev ntev ntawm 30% txog 40%, qhia txog kev ua haujlwm zoo. Qhov nyuaj Brinell yog kwv yees li 60 HB, lees paub qhov sib xws zoo ntawm qhov vuam thiab cov khoom siv tooj liab, thiab muab lub zog txaus rau ntau daim ntawv thov kev lag luam uas cov khoom tooj liab tiv taus kev ntxhov siab ua haujlwm.

ERCutooj liab hlau vuam hlauua ke cov hluav taws xob zoo heev, lub zog kho tshuab, thiab weldability. Cov yam ntxwv no ua rau hom hlau tooj liab no tseem ceeb heev hauv cov teb xws li kev tsim hluav taws xob, cov kav dej, thiab kev txij nkawm hauv kev lag luam, qhov twg tooj liab txhim khu kev qha rau kev sib txuas tooj liab yog qhov tseem ceeb. Nws cov khoom siv lub cev thiab lub tshuab zoo tshaj plaws ua kom ntseeg tau tias kev vuam sib xws hauv ntau yam kev siv vuam thoob plaws kev tsim khoom thiab kev kho.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-11-2025