AWS A5.7 ERCuSn-C Phosphor Bronze hlau

Kev Taw Qhia

Pom zoo rau kev vuam tooj liab nrog Cu-Sn alloy. Zoo tshaj plaws rau kev vuam tooj dag nrog hlau. Pom zoo kom ua kom sov ua ntej rau cov khoom loj, thiab kev vuam pulsed argon arc yog pom zoo rau kev vuam ntau txheej ntawm hlau.

| Kev Tswj Tus Qauv: | Cim lej: | |

| GB/T9460-2008 | SCu5210 | |

| AWS A5.7:2007 | ERCuSn-C | |

| BS EN14640: 2005 | Cu 5210 | |

| Cov khoom sib xyaw (tus nqi txheem): | % | |

| Cu incl.ag | pob. | |

| Zn | 0.20 | |

| Sn | 7.00-9.00 | |

| Fe | 0.10 | |

| P | 0.10-0.35 | |

| Al | 0.01 | |

| Pb | 0.02 | |

| Tag nrho lwm tus | 0.50 | |

| Cov khoom siv lub cev ntawm cov ntaub ntawv: | ||

| Qhov Ceev | Kg/m3 | 8.8 |

| Ntau yam yaj | ℃ | 875-1025 |

| Kev ua kom sov tau zoo | W/mK | 66 |

| Kev ua hluav taws xob | Sm/mm2 | 6-8 |

| Coefficient ntawm thermal expansion | 10^-6/K(20-300℃) | 18.5 |

| Tus nqi txheem ntawm cov hlau vuam: | ||

| Kev ntev | % | 20 |

| Lub zog tensile | N/mm2 | 260 |

| Kev ua haujlwm cuam tshuam ntawm cov kab nrib pleb | J | 32 |

| Brinell hardness | HB 2.5/62.5 | 80 |

| Cov ntawv thov: | ||

| Cov hlau tooj liab uas muaj tin ntau dua - ua rau muaj zog dua rau kev vuam overlay. Tshwj xeeb tshaj yog rau kev vuam cov khoom siv tooj liab, xws li tooj liab, tin bronzes, tshwj xeeb tshaj yog siv rau kev sib koom ua ke ntawm tooj liab zinc alloys thiab hlau. Haum rau kev kho vuam ntawm cov bronzes cam khwb cia thiab rau kev vuam qhov cub. Rau kev vuam ntau txheej ntawm hlau, kev vuam pulsed arc yog qhov pom zoo. Rau cov khoom ua haujlwm loj, kev ua ntej cua sov yog qhov pom zoo. | ||

| Ua kom tiav: | ||

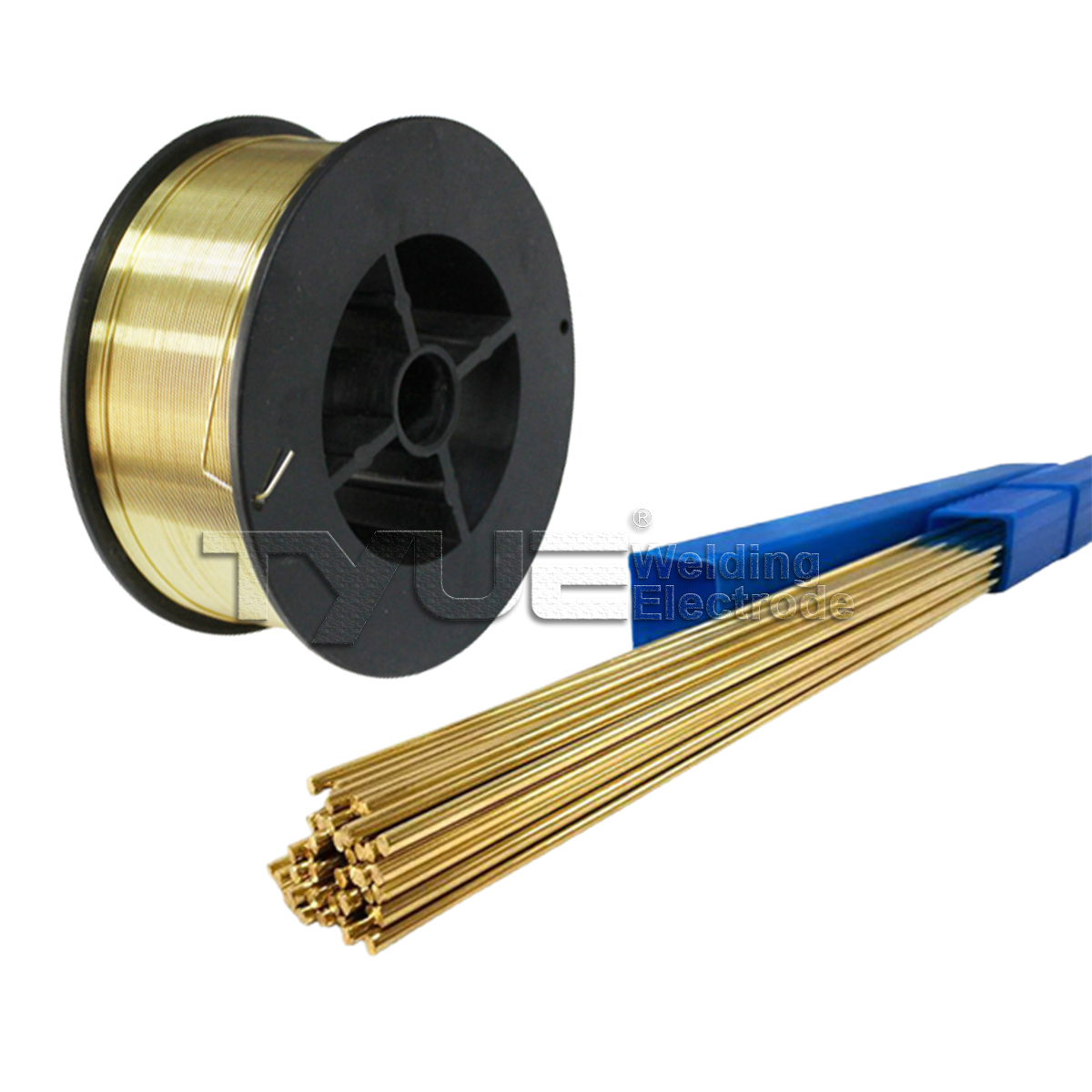

| Txoj kab uas hla: 0.64 – 0.80 – 1.00 – 1.20 – 1.60 -2.40 | ||

| Cov khoom siv: D100, D200, D300, D760, K300, KS300 | ||

| Cov pas nrig: 1.60 - 9.6 hli x 914/1000 hli | ||

| Cov electrodes muaj. | ||

| Ua kom tiav ntxiv raws li qhov xav tau. | ||

Wenzhou Tianyu Electronic Co., Ltd. tau tsim muaj xyoo 2000. Peb tau koom nrog kev tsim cov electrodes vuam, cov pas nrig vuam, thiab cov khoom siv vuam rau ntau tshaj 20 xyoo.

Peb cov khoom tseem ceeb suav nrog cov hlau tsis xeb vuam electrodes, carbon hlau vuam electrodes, qis alloy vuam electrodes, surfacing vuam electrodes, nickel & cobalt alloy vuam electrodes, mild steel & low alloy vuam wires, stainless hlau vuam wires, gas-shielded flux cored wires, txhuas vuam wires, submerged arc vuam. wires, nickel & cobalt alloy vuam wires, tooj dag vuam wires, TIG & MIG welding wires, tungsten electrodes, carbon gouging electrodes, thiab lwm yam khoom siv vuam & khoom siv tau.