APPLICATIONS:

Vuam ntawm 9% Cr-1% Mo steels thiab 9% Cr - 2% Mo steels siv rau lub zog hluav taws xob thiab cov hlab ntsha siab.

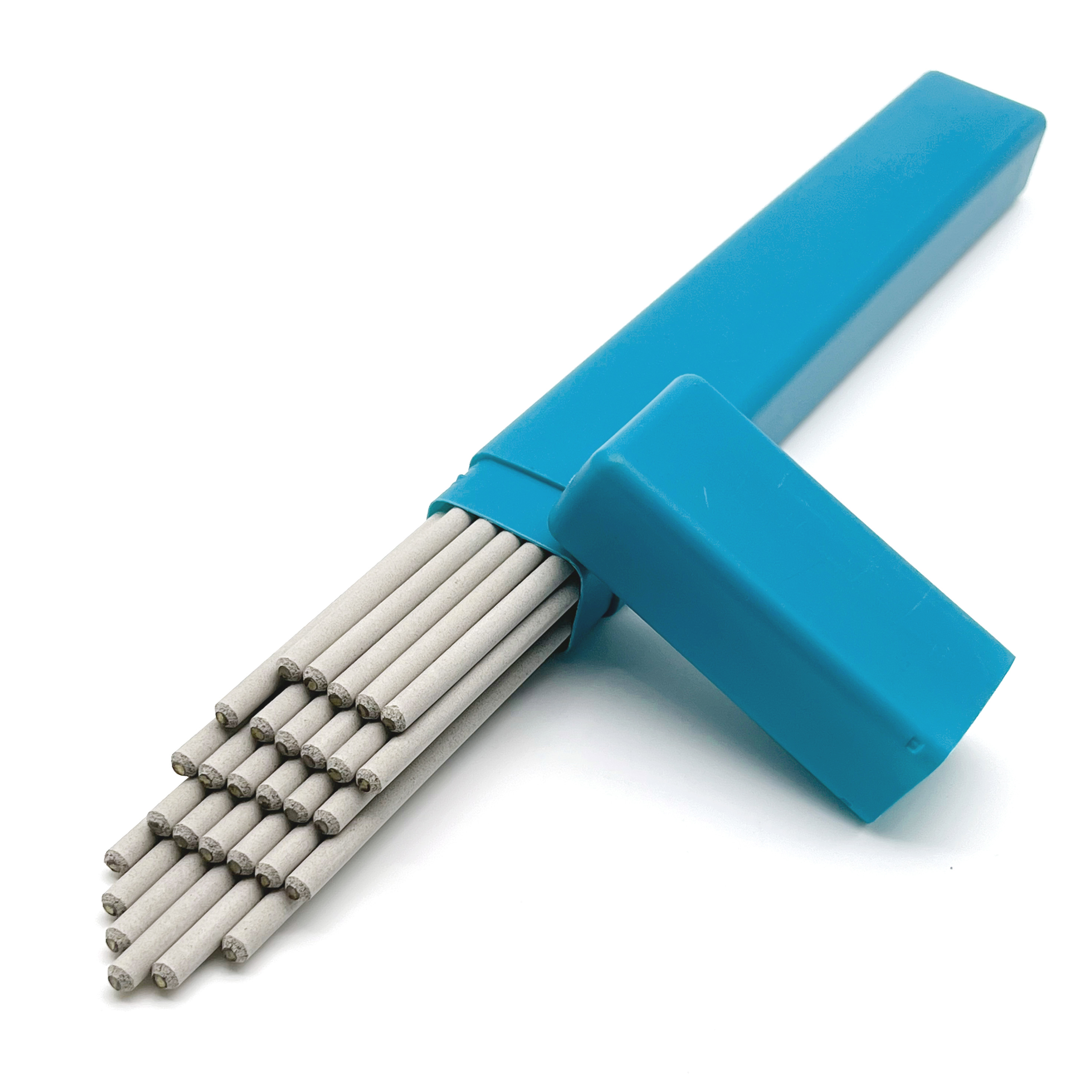

NTAUB NTAWV:

PA-8016-B8 yog ib qho tsis tshua muaj hydrogen electrode uas nws cov hlau vuam muaj 9% Cr-1% Mo.Nws yog tsim los rau kub kub hlau thiab steels rau kub hydrogen kev pab cuam, tshwj xeeb tshaj yog nyob rau hauv petrochemical kev lag luam.Cov electrode tuaj yeem pom zoo rau nws lub zog tensile siab, zoo toughness thiab zoo kub kuj.

CEEB TOOM RAU SIV:

1. Qhuav cov electrodes ntawm 350-400 ° C li ntawm ib teev ua ntej siv thiab khaws cov electrodes ntawm 100-150 ° C tom qab ziab lawv nrog ceev faj kom tsis txhob ya raws.

2. Txais cov txheej txheem rov qab los yog ntaus lub arc ntawm lub phaj me me uas npaj rau lub hom phiaj tshwj xeeb no kom tsis txhob muaj lub tshuab cua ntawm lub arc pib.

3. Khaws lub arc kom luv li sai tau.

4. Preheat ntawm 100-150 ° C.Qhov kub yuav tsum tau thov txawv raws li phaj thickness thiab hom hlau yuav tsum tau welded.

5. Ua tib zoo saib kom tsis txhob muaj cov cua sov kom zoo vim tias cov khoom siv hluav taws xob ntau dhau ua rau muaj kev cuam tshuam cov txiaj ntsig thiab cov txiaj ntsig zoo ntawm cov hlau weld.

IV.TYPICAL CHEMICAL COMPOSITION OF WELD METAL (%):

| C | Si | Mn | Cr | Mo |

| 0.06 ib | 0.42 ib | 0.68 ib | 9.38 ib | 1.05 Nws |

V. TYPICAL MECHANICAL PROPERTIES OF WELD METAL:

| Tensile zog N / mm2(Ksi) | Yield Point N/mm2 (Ksi) | Elongation% | PWHT |

| 705 (102) hnub | 560 (81) | 24 | 740°C x 1 h |

VI.WELDING POSITIONS: Txhua txoj haujlwm

VII.SIJHAWM THIAB SAIB XYUAS KOM ZOO (AC/DC+):

| Txoj kab uas hla (mm) | 2.5 | 3.2 | 4.0 | 5.0 | |

| Ntev (mm) | 350 | 350 | 400 | 400 | |

| Ampere | Pav ca | 55-85 : kuv | 90-130 : kuv | 130-180 Nws | 180-240 : kuv |

| V & OH | 50-80 | 80-115 : kuv | 110-170 ib | 150-200 |