| Steel qib hom | Pwm steel: |

| Txuj |

|

| Ntau lawm specifications | Hlau phaj, Sheet, Chev, Pav ca bar, Round bar, Sawb steel, hlau, Txhua yam forgings. |

| Mchining | Tig Milling Sib tsoo Qhov tob qhov drilling: ntev max 9.8 meters. |

| Ntau yam ntawm kev ua haujlwm | Round bar steel: 1mm txog 2000mm Square-puab steel: 10mm txog 1000mm steel phaj / ntawv: 0.08mm txog 800mm Dav: 10mm txog 1500mm Lenth: Peb tuaj yeem muab txhua qhov ntev raws li cov neeg siv khoom xav tau. Forging: Shafts nrog flanks / kav / raj / slugs / donuts / cubes / lwm yam duab Tubings: OD: φ4-410 hli, nrog phab ntsa thickness li ntawm 1-35 hli. |

| Kev kho cua sov | Normalizing, Annealing, Tempering, Quenching, Hardening thiab tempering, Seasoning, Deg hardening, Carburizing |

AWS E10015-D2 CHEMICAL COMPOSITION AND MECHANICAL PROPERTESL:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 Nws | 0.03 ib | 0.03 ib | ≤ 0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 Nws | ||||||

| N | Co | Pb | B | Lwm yam |

MECHANICAL PROPERTIES:

| Cov khoom | Cov xwm txheej | ||

| T (° C) | Kev kho mob | ||

| Qhov ceev (× 1000 kg / m3) | 7.7-8.03 Nws | 25 |

|

| Poisson tus ratio | 0.27-0.30 Nws | 25 |

|

| Elastic Modulus (GPa) | 190-210 : kuv | 25 |

|

| Tensile zog (Mpa) | 1158 ib | 25 | roj quenched, fine grained, tempered ntawm 425 ° C |

| Yield zog (Mpa) | 1034 ib | ||

| Elongation (%) | 15 | ||

| Kev txo qis hauv cheeb tsam (%) | 53 | ||

| Hardness (HB) | 335 | 25 | roj quenched, fine grained, tempered ntawm 425 ° C |

| Cov khoom | Cov xwm txheej | ||

| T (° C) | Kev kho mob | ||

| Thermal conductivity (W / mK) | 42.7 ib | 100 | |

| Thaum tshav kub kub (J / kg-K) | 477 ib | 50-100 | |

PHYSICAL PROPERTIES:

| Ntau | Tus nqi | Chav tsev |

| Thermal expansion | 16–17 | e-6/K |

| Thermal conductivity | 16-16 | W/mK |

| Tshwj xeeb kub | 500-500 | J/Kg |

| Melting kub | 1370-1400 Nws | °C |

| Kev pabcuam kub | 0-500 | °C |

| Qhov ntom | 8000-8000 | kg/m3 |

| Kev tiv thaiv | 0.7-0.7 hli | Ohm.mm2/m |

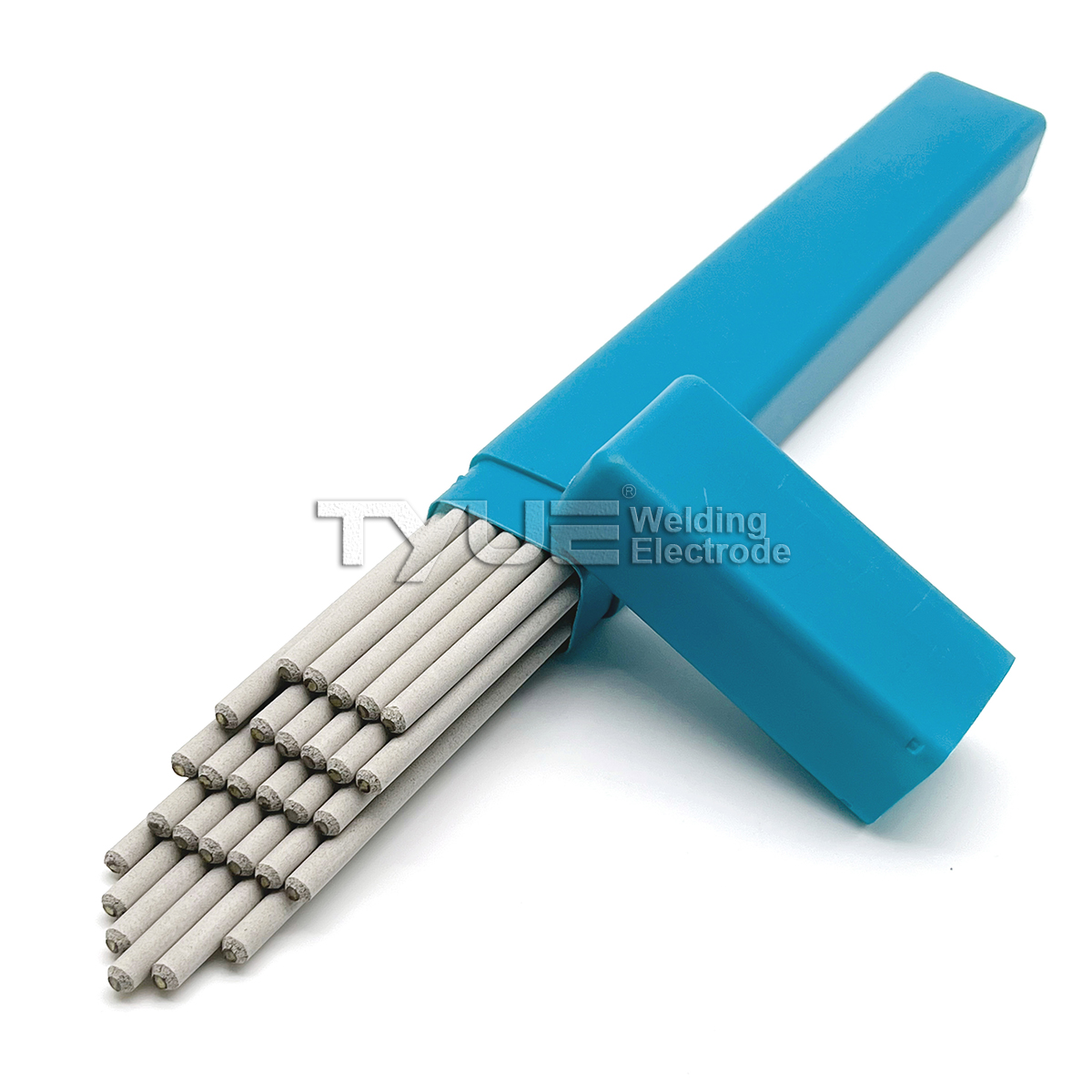

E7015-G Tsawg Hydrogen Sodium Txheej Vuam Electrodes

DESCRIPTION:

Nws yog qhov kub tsis tshua muaj steel vuam pas nrig nrog qis sodium hydrogen txheej uas muaj npib tsib xee.Tag nrho txoj haujlwm welding tuaj yeem ua tau los ntawm dc rov qab txuas.Nyob rau hauv -80 ° C weld hlau tseem muaj kev cuam tshuam zoo toughness.

SIV:

Welded -80 ° C ua haujlwm 1.5Ni steel qauv.

DEPOSITED METAL CHEMICAL COMPOSITION:

| C | Mn | Si | Ni | S | P | |

| Txuj | ≤ 0.08 | ≤1.25 | ≤ 0.60 | ≥1.00 Nws | ≤ 0.035 | ≤ 0.035 |

| Kuaj | 0.045 ib | 0.60 ib | 0.27 ib | 1.80 ib | 0.010 ib | 0.015 ib |

DEPOSITED METAL MECHANICAL PERMANCE:

| Tensile zog Rm (MPa) | Yield zog Rel (MPa) | Elongation A (%) | -80 ° C Tus nqi cuam tshuam Akv (J) | |

| Txuj | ≥490 | ≥390 | ≥ 22 | ≥ 27 |

| Kuaj | 530 | 445 | 30 | 100 |

REFERENTIAL CURRENT (DC+):

| Txoj kab uas hla (mm) | 3.2 | 4.0 | 5.0 | |

| Ntev (mm) | 350 | 400 | 400 | |

| Tam sim no (A) | 90-120 : kuv | 140-180 : kuv | 180-210 : kuv |

| E12015-G | Raws li GB E8515-G AWS E12015-G |

Taw qhia: E12015-G yog hom qis-alloy siab zog steel electrode nrog qis-hydrogen natrium hom txheej.DCRP (Direct Current Reversed Polarity).Txhua txoj hauj lwm welding.

Daim ntaub ntawv: Siv rau vuam qis-alloy siab zog steel qauv nrog tensile lub zog ntawm txog 830MPa.

Chemical Composition ntawm Deposited Hlau (%)

| Tshuaj muaj pes tsawg leeg | C | Mn | Si | S | P | Mo |

| Guarantee Tus nqi | ≤ 0.15 | ≥1.00 Nws | 0.4 ~ 0.8 hli | ≤ 0.035 | ≤ 0.035 | 0.60-1.20 Nws |

| General Result | ≤ 0.10 | ~ 1.50 | ≤ 0.70 | ≤ 0.020 | ≤ 0.020 | ~ 0.90 Nws |

Mechanical Properties of Deposited Hlau

| Cov khoom kuaj | Rm(MPa) | ReL lubRp0.2 ua(Mpa) | A(%) | KV2(J) |

| Guarantee Tus nqi | ≥830 | ≥740 | ≥12 | -(qhov kub thiab txias) |

| General Result | 860-950 : kuv | ≥750 | 12-20 : kuv | ≥ 27 |

Diffusible Hydrogen Cov ntsiab lus hauv Deposited Hlau: ≤5.0ml / 100g (Chromatography)

X-ray Radiographic Inspection: ⅠDegree

Cov lus qhia:

1.Cov electrodes yuav tsum tau ci hauv qab 350-400 ℃ rau ib teev ua ntej welding, muab tso rau hauv ib lub rwb thaiv tsev tuaj yeem thiab thov sai li sai tau raws li lawv xav tau.

2.Cov stains ntawm lub vuam zoo li xeb yuav tsum tau muab tshem tawm, thiab cov vuam yuav tsum tau preheated txog 200 ℃.

3.Weld tuaj yeem tempered hauv qab 600-650 ℃ tom qab vuam kom tshem tawm kev ntxhov siab sab hauv.