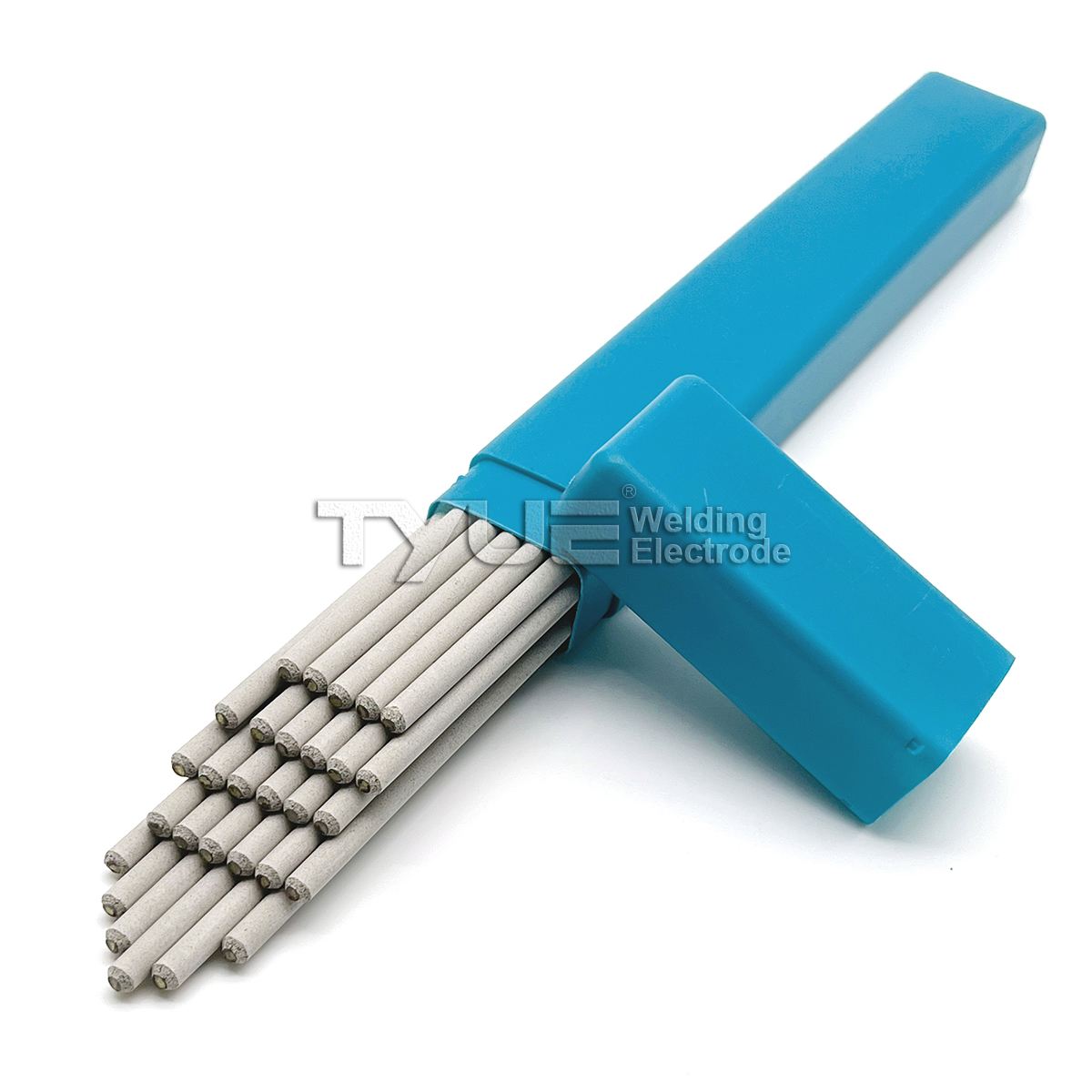

Cov Hlau Sib Txuas Qis

J556Fe

GB/T E5518-G

AWS E8018-G

Kev piav qhia: J556fe yog lub electrode hlau tsis tshua muaj hlau nrog hmoov hlau thiab txheej hydrogen tsawg. Ob qho tib si AC thiab DC tuaj yeem siv, thiab tuaj yeem vuam rau txhua qhov chaw.

Daim Ntawv Thov: Siv rau kev vuam cov hlau carbon nruab nrab thiab cov qauv hlau tsis tshua muaj hlau xws li Q390.

Cov tshuaj lom neeg muaj pes tsawg leeg ntawm cov hlau vuam (%):

| C | Mn | Si | S | P |

| ≤0.12 | ≥1.00 | ≤0.80 | ≤0.035 | ≤0.035 |

Cov khoom siv kho tshuab ntawm cov hlau vuam:

| Khoom sim | Lub zog tensile Mpa | Lub zog tawm los Mpa | Kev ntev % | Tus nqi cuam tshuam (J) -40 ℃ |

| Tau lees paub | ≥540 | ≥440 | ≥17 | ≥27 |

Cov ntsiab lus hydrogen diffusion ntawm cov hlau tso: ≤10.0mL / 100g (mercury lossis roj chromatography txoj kev)

Kev tshuaj xyuas X-ray: Kuv qib

Pom zoo tam sim no:

| (hli) Txoj kab uas hla ntawm tus pas nrig | 2.5 | 3.2 | 4.0 | 5.0 |

| (Ib) Vuam Tam Sim No | 70 ~ 110 | 100 ~ 140 | 140 ~ 170 | 190 ~ 240 |

Daim Ntawv Ceeb Toom:

1. Lub electrode yuav tsum tau ci rau 1 teev ntawm 350 ℃ ua ntej vuam ua haujlwm;

2. Nws yog ib qho tseem ceeb uas yuav tsum tau ntxuav cov xeb, roj nplai, dej, thiab cov khoom tsis huv ntawm cov khoom vuam ua ntej vuam;

3. Siv txoj kev vuam luv luv thaum vuam. Txoj kev vuam nqaim yog qhov tsim nyog.