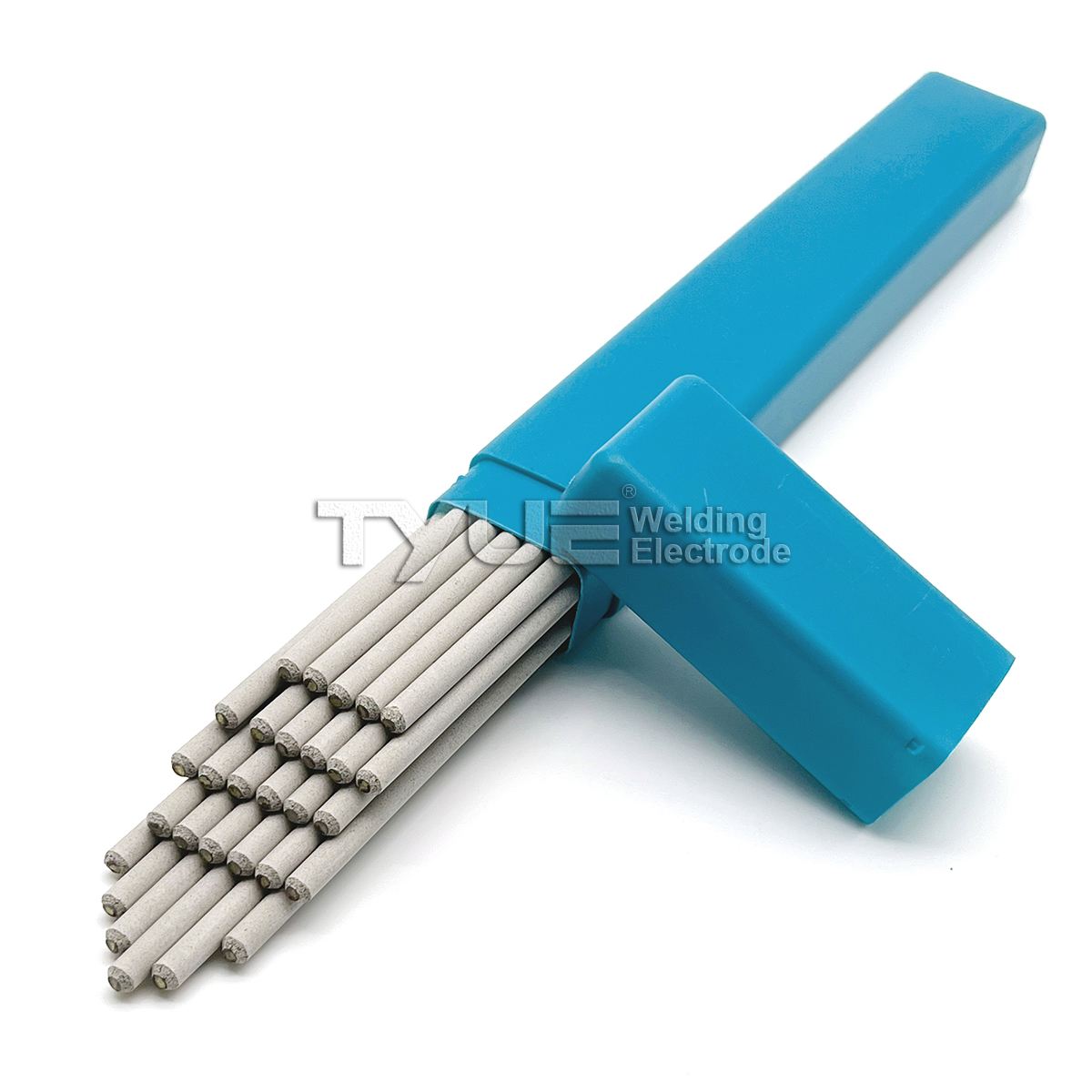

Tsawg AlloyHlau VuamHluav taws xob

j607 ua

GB/T E6015-D1

AWS E9015-D1

Nqe lus piav qhia: J607 yog cov hlau tsis tshua muaj zog hlau electrode nrog qis-hydrogen sodium txheej.Siv DCEP (cov khoom siv hluav taws xob ncaj qha tam sim no), thiab tuaj yeem txuas rau txhua txoj haujlwm.

Daim ntawv thov: Siv rau vuam nruab nrab carbon steel thiab low-alloy high-strength steel qauv ntawm coj lub zog, xws li Q420, thiab lwm yam.

Tshuaj muaj pes tsawg leeg ntawm weld hlau (%):

| C | Mn | Si | Mo | S | P |

| ≤ 0.12 | 1.25-1.75 Nws | ≤0.60 | 0.25 ~ 0.45 hli | ≤ 0.035 | ≤ 0.035 |

Mechanical zog ntawm weld hlau:

| Cov khoom kuaj | Tensile zog Mpa | Yield zog Mpa | Elongation % | Tus nqi cuam tshuam (J) -30 ℃ |

| lav | ≥590 | ≥490 | ≥15 | ≥ 27 |

| Kuaj | 620 ~ 680 ib | ≥500 | 20 ~ 28 | ≥ 27 |

Diffusion hydrogen ntsiab lus ntawm deposited hlau: ≤4.0mL / 100g (glycerin method)

X-ray kuaj: qib kuv

Pom zoo tam sim no:

| (mm) Qws txoj kab uas hla | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 5.8 |

| (A) Vuam tam sim no | 60 ~ 80 | 70 ~ 90 ib | 90 ~ 120 hli | 140 ~ 180 ib | 170-210 ib | 210-260 ib |

Daim ntawv ceeb toom:

1. Cov electrode yuav tsum tau ci rau 1 teev ntawm 350 ℃ ua ntej vuam ua haujlwm;

2. Nws yog ib qho tseem ceeb los ntxuav cov xeb, roj nplai, dej, thiab impurities ntawm vuam qhov chaw ua ntej vuam;

3. Siv luv arc ua haujlwm thaum vuam.Txoj kev nqaim welding yog tsim nyog.