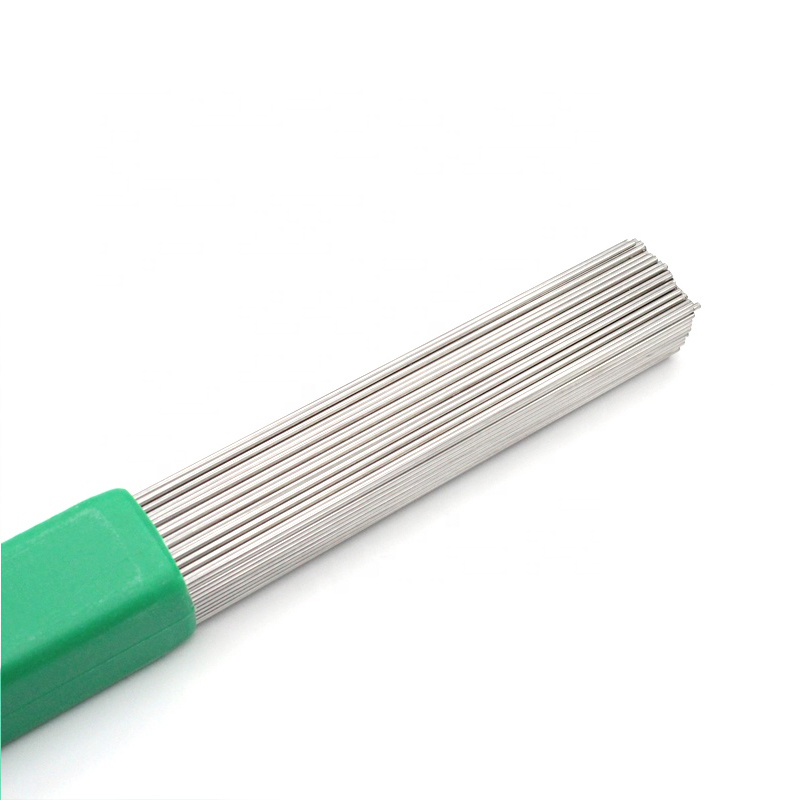

ER5183 yog tsim rau MIG vuam cov txhuas magnesium alloy uas xav tau lub zog tensile siab dua thiab yog tias cov hlau puag yog 5083 lossis 5654 lub zog tensile yuav siab dua. Nws yog dav siv rau kev vuam txhuas magnesium alloy cov qauv ntawm cov nkoj, cov platforms offshore, locomotives & carriages, tsheb, thawv, cryogenic hlab ntsha thiab lwm yam. Nws cov hlau weld muaj kev tiv thaiv zoo rau brine corrosion.

Txoj Haujlwm Vuam: F, HF, V

Hom Tam Sim No: DCEP

DAIM NTAWV CEEV:

Khaws lub pob ntawm cov hlau kom zoo ua ntej vuam.

Ob qho chaw uas yuav tsum tau welded ntawm weldment thiab hlau yuav tsum tau ntxuav kom huv si ntawm cov roj av, oxide txheej, noo noo thiab lwm yam.

Yuav kom tau txais qhov zoo nkauj ntawm qhov vuam, nws yog qhov tsim nyog los ua kom sov lub hauv paus hlau rau 100 ℃ -200 ℃ ua ntej vuam yog tias nws cov tuab yog 10 hli lossis ntau dua.

Nws yog qhov zoo dua los muab lub subplate nyob rau hauv qab thaj chaw vuam kom txhawb cov hlau yaj kom ntseeg tau tias kev nkag mus rau hauv qhov vuam tiav.

Raws li qhov chaw vuam thiab qhov tuab ntawm cov hlau hauv paus, yuav tsum xaiv cov roj tiv thaiv sib txawv, xws li 100% Ar, 75% Ar + 25% He, 50% Ar + 50% He, thiab lwm yam.

Cov xwm txheej vuam uas tau hais los saum toj no tsuas yog siv rau kev siv xwb thiab nws zoo dua los ua qhov kev tsim nyog ntawm cov txheej txheem vuam raws li qhov project ua ntej muab tso rau hauv kev vuam raug cai.

ER5183 COV KHOOM SIV NTAWM COV HLAU DEPOSITED (%):

| SI | FE | CU | MN | MG | CR | ZN | TI | AI | BE | |

| Tus Qauv | ≤0.40 | ≤0.40 | ≤0.10 | 0.50-10 | 4.3-52 | 0.05-0.5 | ≤0.25 | ≤0.15 | Qhov Nyiaj Tshuav | ≤0.0003 |

| Ib txwm muaj | 0.08 | 0.12 | 0.006 | 0.65 | 4.75 | 0.130 | 0.005 | 0.080 | Qhov Nyiaj Tshuav | 0.0001 |

COV KHOOM SIV NTAWM COV HLAU DEPOSITED (AW):

| Lub zog tensile RM (MPA) | Lub zog ua kom muaj zog (MPA) | KEV NTXIV A4 (%) | |

| Ib txwm muaj | 280 | 150 | 18 |

Qhov Loj & Cov Lus Qhia Tam Sim No rau MIG (DC +):

| Txoj kab uas hla ntawm txoj hlua vuam (MM) | 1.2 | 1.6 | 2.0 |

| Vuam Tam Sim No (A) | 180-300 | 200-400 | 240-450 |

| Vuam Voltage (V) | 18-28 | 20-20 | 22-34 |

Qhov Loj & Qhov Tam Sim No Pom Zoo Rau TIG (DC¯):

| Txoj kab uas hla ntawm txoj hlua vuam (MM) | 1.6-2.5 | 2.5-4.0 | 4.0-5.0 |

| Vuam Tam Sim No (A) | 150-250 | 200-320 | 220-400 |

Wenzhou Tianyu Electronic Co., Ltd. tau tsim muaj xyoo 2000. Peb tau koom nrog kev tsim cov electrodes vuam, cov pas nrig vuam, thiab cov khoom siv vuam rau ntau tshaj 20 xyoo.

Peb cov khoom tseem ceeb suav nrog cov hlau tsis xeb vuam electrodes, carbon hlau vuam electrodes, qis alloy vuam electrodes, surfacing vuam electrodes, nickel & cobalt alloy vuam electrodes, mild steel & low alloy vuam wires, stainless hlau vuam wires, gas-shielded flux cored wires, txhuas vuam wires, submerged arc vuam. wires, nickel & cobalt alloy vuam wires, tooj dag vuam wires, TIG & MIG welding wires, tungsten electrodes, carbon gouging electrodes, thiab lwm yam khoom siv vuam & khoom siv tau.